The phenomenon of freezing of heat exchanger of small chiller is very common. The solution proposed by us can completely solve the freezing of heat exchanger caused by water flow through reasonable matching of differential pressure flow switch.

User profile

▶ Household air cooled chillers and small water - water chillers are often used in homes, shops and small buildings.

▶ There is no special maintenance management personnel, users are very concerned about operating costs, and air conditioning units will not do regular maintenance.

▶ The user does not have professional knowledge, and it is basically a simple on-off operation.

If there is any problem, the maintenance personnel of the air conditioning manufacturer are often called for help, and sometimes the maintenance personnel of the manufacturer will run the wrong way, and some unnecessary costs will be generated.

According to the actual use of customers, to meet the needs of customers

▶ In addition to the design of the pipeline components of the chiller, the water pipes outside the unit must also use non-rusting pipes, which can reduce the maintenance of the user's water pipes.

This requires that the water flow switch of the unit can correctly protect the unit when the water flow is reduced during user operation, and can not cause the fault alarm because there is air in the water pipe to make the water flow switch operate incorrectly. Each fault alarm will give the user a bad experience, and may increase the manufacturer's detection and maintenance costs.

▶ The manufacturer is not only responsible for the quality of the chiller, but also responsible for the quality of the entire air conditioning system. The user requires the energy saving of the entire air conditioning system, not only the energy saving of the chiller.

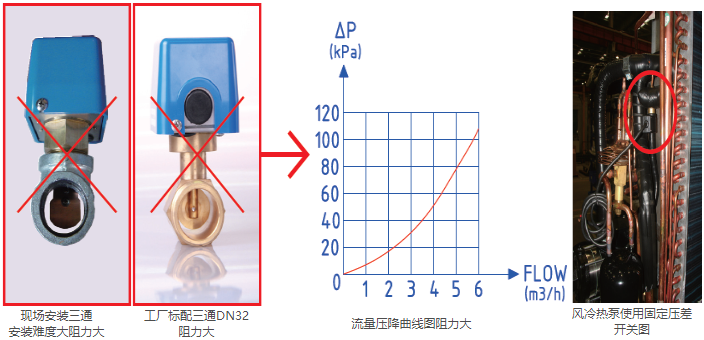

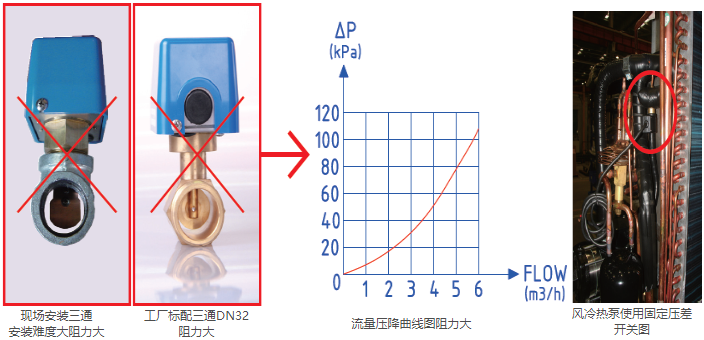

Disadvantages of using traditional target water flow switches in small chiller units

▶ Affected by the technical level of the installation personnel and the diameter of the water pipe, the small pipe diameter is easy to get stuck, and the success rate of one installation is more than 60%.

▶ The water system produces a pressure drop of 3 to 5 meters of water column, and the effective head provided to the customer is reduced, resulting in the water flow of the chiller, the operation energy efficiency of the chiller is also significantly decreased, and the energy consumption of the pump is increased by 5 to 10%, which is a meaningless waste of energy for the user and the society.

▶ The flow cannot be accurately controlled, there is no clear action and reset flow, even if the factory is equipped with tee and adjusted flow setting value, because the flow switch internal bellows are affected by static pressure on site, the flow setting value will have a large offset. If the target flow switch cannot be opened on site, it is often adjusted by the installation and debugging personnel to close the flow switch and fail without checking the cause.

Easy to misoperate, because when the air in the water pipe is not discharged, the bubbles formed by it impact the target, resulting in changes in the flow rate and frequent reset of the water flow switch. If the delay time is not set in the control loop, it is easy to cause frequent start and stop of the host. If the delay time is set, the compressor will continue to run when there is no water flow, which may lead to the freezing failure of the evaporator.

Advantages of using the WFS10 series differential flow switch in small chiller

▶ Installed in the unit by the factory, the factory controls the installation quality of the most important protective parts of the chiller, and it is easier to install the pressure from both ends of the heat exchanger.

▶ The water pipe does not produce any pressure drop, does not consume any lift of the pump, the effective lift obtained by the user is increased, the water flow of the unit is guaranteed, the unit operation efficiency is also improved, the chance of the unit failure is reduced, and it is more energy saving.

▶ The pressure differential flow switch is accurately matched between the factory and the heat exchanger, with accurate action and reset flow, and the user cannot change the set value on the site. The setting value of the factory is protected, according to which the manufacturer can determine whether the water flow of the unit meets the requirements. Before, the manufacturer could not measure the water flow on the site, but now it can basically determine whether it meets the minimum flow of the unit. The precise operating flow protection value can prevent the heat exchanger from freezing when the flow rate is too low.

▶ Even if there is air in the water pipe, there will be no misoperation, every action is real and reliable, and the control system can do no delay processing to avoid the freezing of the heat exchanger caused by the delay of stopping the compressor when the water flow is insufficient.

Application of antifreeze solution for heat exchanger of small chiller

▶ Since the introduction of this solution nationwide in 2002, there are other contents in the solution besides differential pressure flow switch. We have trained more than 100 design engineers in air conditioning manufacturers nationwide to help them adopt this solution to improve their designs. At present, more than 300,000 chillers use this solution, which directly reduces the failure loss of more than 100 million yuan, and the energy saving effect is also very significant.

▶ At present, more than 100 central air conditioning brands in the country adopt our solution, and the freezing rate of the heat exchanger of the air conditioning unit has also dropped from a few percent to a few thousand, and the failure rate of our product itself is less than a few thousand. At present, it has been widely verified by world-class central air conditioning brands for more than 10 years, and it is the most reliable heat exchanger antifreeze solution for small central air conditioning.